Technology Overview

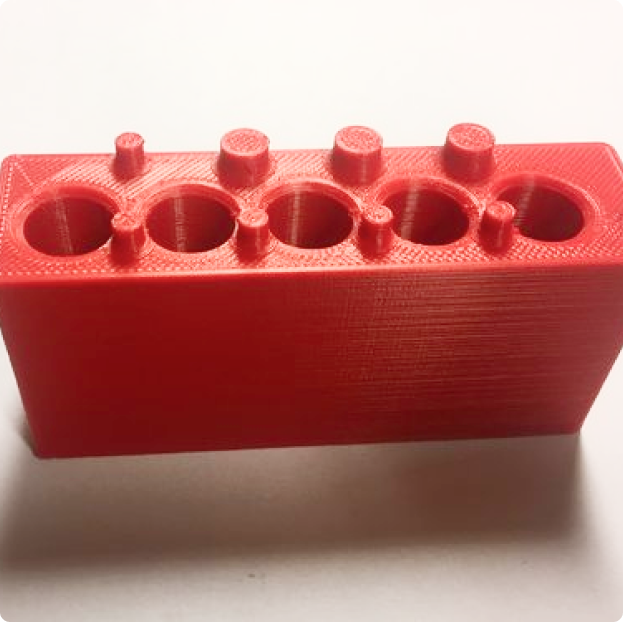

By using a laser to selectively melt a 0.1 mm thick layer of nylon powder, our industrial SLS 3d printers build durable items with few design constraints. As the item is built on a bed of powder, unlike other 3d printing technologies, SLS 3d printers don’t require any support material and can therefore benefit from a complete freedom in terms of product design.

While the unprocessed items are white out of the printer, 3d printed nylon can easily be dyed, and we offer a wide range of colours to which we can dye your items.

Industrial SLS Use-cases

Product Development

With lead-times of just 1–2 days and visual properties similar to those of other production methods, SLS is an ideal technology for product development.

- Interlocking parts

- Design freedom

- High accuracy

Volume Production

With high productivity machines producing excellent mechanical and visual quality, SLS is a perfect technology for volume production.

- No tooling costs

- High production speed

- Easily scalable

Functional Parts

When using PA12 nylon, SLS technology is perfect to use for parts that must withstand high stresses and loads.

- Strong and durable

- Isometric properties

- Chemically resistent

Our SLS Machinery

Our SLS printing farm is based around a combination of proprietary machines and machines made by renowned german manufacturer EOS. Our automated machines are able to start new print-jobs 24/7 allowing true volume manufacturing using SLS 3d printing technology, therefore being an exceptionally cost-efficient method to go from prototyping to mass manufacturing.

Combined with our finishing systems for surface cleaning, treatment and dyeing, we use our SLS production systems to produce items with market-leading visual and mechanical properties.

SLS Materials

We currently only offer one material for our SLS 3d printing service: Nylon PA12. Combined with our post-processing and finishing systems, we are able to offer 3d printing services for a wide variety of applications ranging from visual prototypes to mass manufacturing of engineering items with strict mechanical requirements.

Polyjet Full Color

Using Polyjet technology, we produce highly detailed, full-color models with exceptional precision and finish options.

PA12 Carbonfiber

Carbon-fiber reinforced nylon. Added carbon-fiber makes this one of our stiffest materials.

High-detail Resin

Engineered to capture the smallest details. Great for parts with texts and extreme features.

Visual Resin

or "Standard Resin". Perfect for visual prototypes and decorative objects. Usually too brittle for functional parts.

PC

One of our strongest materials offered, perfect combination of mechanical properties and temperature stability.

Biodegradable PHA

Fully compostable, as well as being approved by the FDA for food contacts. Safe to use in a dishwasher.

PLA Metal-fill

PLA-based material composed of approximately 20-40% metal by weight. For aesthetic purposes.