3d Printing Services

RapAdd MFG offer one of the most versatile and competitive 3d printing services on the market. Using fully automated industrial 3d printers, we are able to produce high-quality 3d printed items in-house using FDM, SLA and SLS technologies, from over 150 different material and colour-combinations. Thanks to our automated industrial 3d printers, we can serve businesses and individuals alike, offering some of the cheapest 3d printing services to be found. Through our high-capacity 3d printing farm, we’ve produced over 500 000 items to date, servicing more than 10 000 unique customers with prototypes, one-offs and serial-production products. Backed by automation, we can produce your project, in a cost-efficient manner, no matter if you need a single item or 100 000 different ones.

3d printing service technologies

RapAdd MFG offers 3d printing services using the three most common technologies for additive manufacturing.

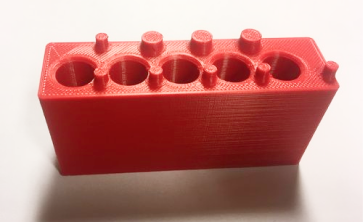

FDM

Being our most automated technology, our industrial FDM 3d printing service is the most versatile manufacturing service that we offer. With a wide range of materials, from PLA to engineering nylons, flame-retardant filaments and PVDF plastics, we have the technology and materials to suit any additive manufacturing project.

Thanks to low costs and short lead-times, FDM printing services are suitable to be used both for one-offs and prototypes as well as for larger production volumes.

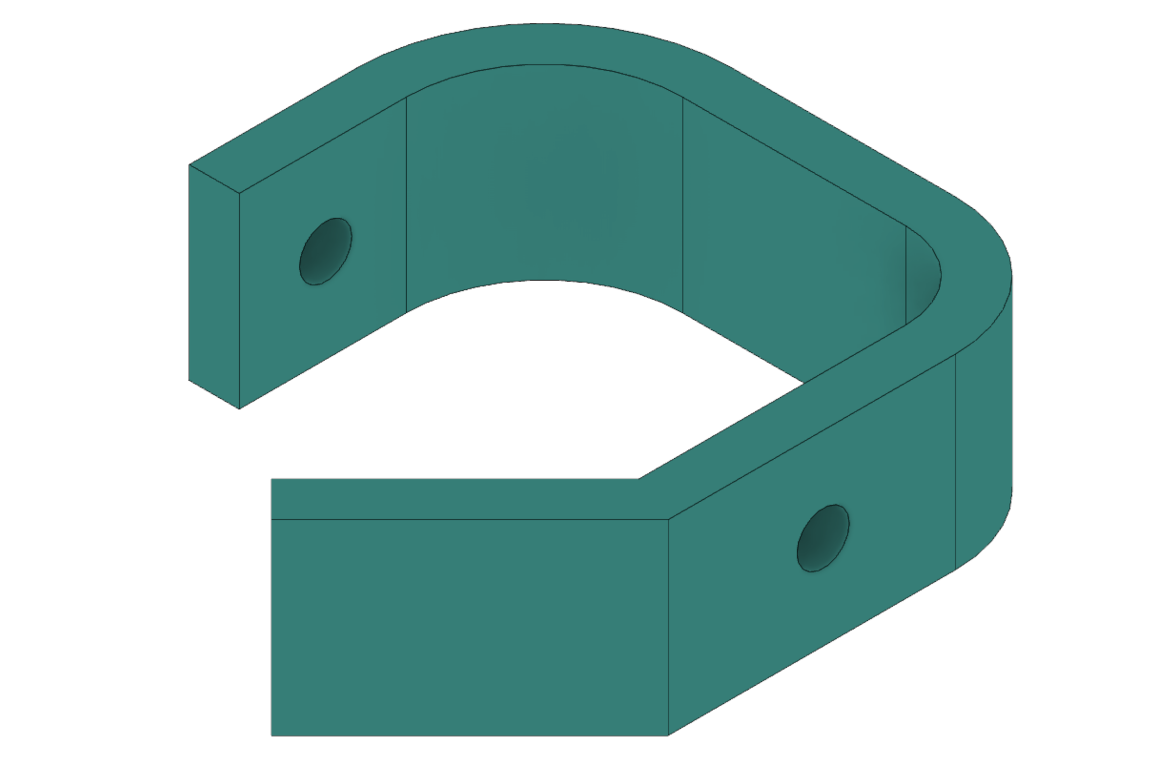

SLS

With our SLS printing service, we can produce items of almost any shape and geometry imaginable from highly durable nylon materials. Being built on a bed of powder, it is possible to produce hundreds of items with highly complex geometries all at once.

Thanks to the high productivity of SLS 3d printing, it is an exceptional method for mass manufacturing of 3d printed goods.

SLA

Our industrial SLA 3d printing service produces items with injection-molding finishes but 3d printing price-levels. By selectively curing a liquid resin with UV-light, we can build geometric features as small as a few tenths of a millimeter.

With a range of different 3d printing resins, we can produce items with many different properties, at a very low price-point.

Capabilities & Design Constraints

While 3d printing is a fantastic method for producing parts, there are some constraints that items still must conform to.

Maximum Part Size

The largest part that may fit in our machines

SLA

275 × 155 × 400 mm

FDM

380 × 380 × 380 mm

SLS

300 × 300 × 500 mm

Smallest Feature Size

The smallest feature that can be produced accurately

SLA

0.10 × 0.10 × 0.05 mm

FDM

1.5 × 1.5 × 0.5 mm

SLS

0.20 × 0.20 × 0.12 mm

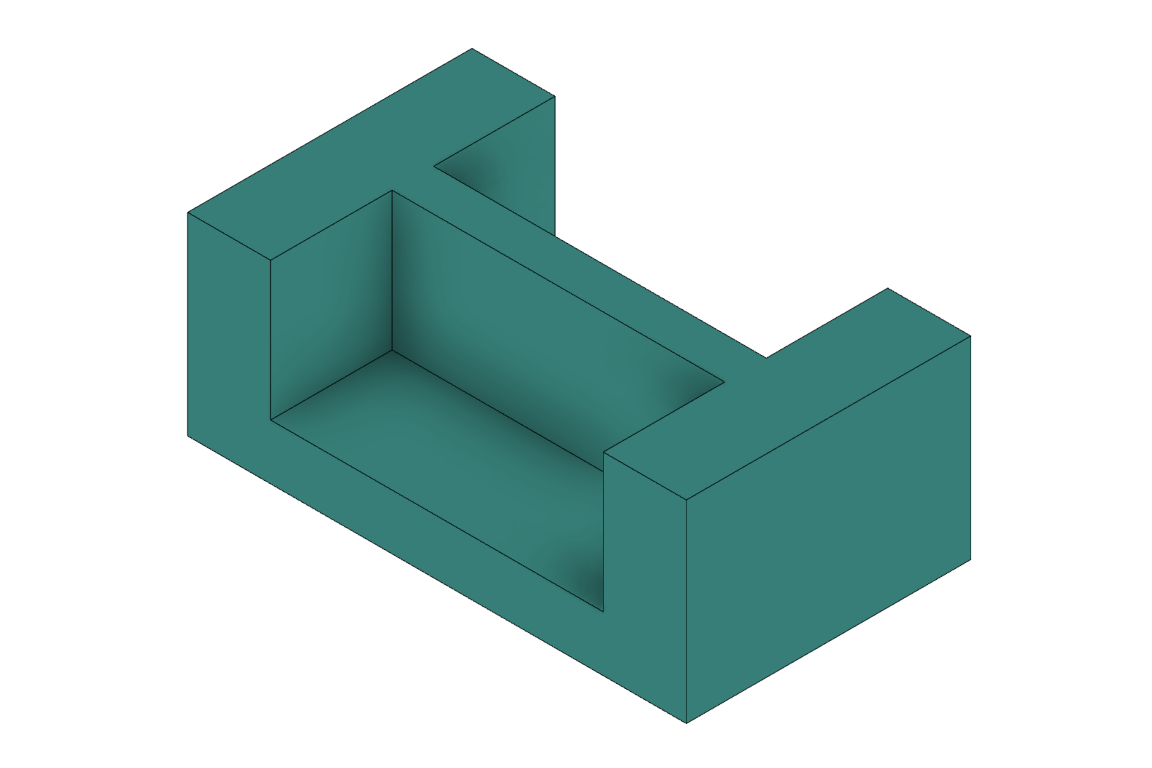

Thinnest Supported Wall

The thinnest wall that can be produced accurately with end support

SLA

0.20 mm

FDM

1.0 mm

SLS

0.5 mm

Thinnest Unsupported Wall

The thinnest wall that can be produced accurately without end support

SLA

0.50 mm

FDM

1.5 mm

SLS

1.0 mm

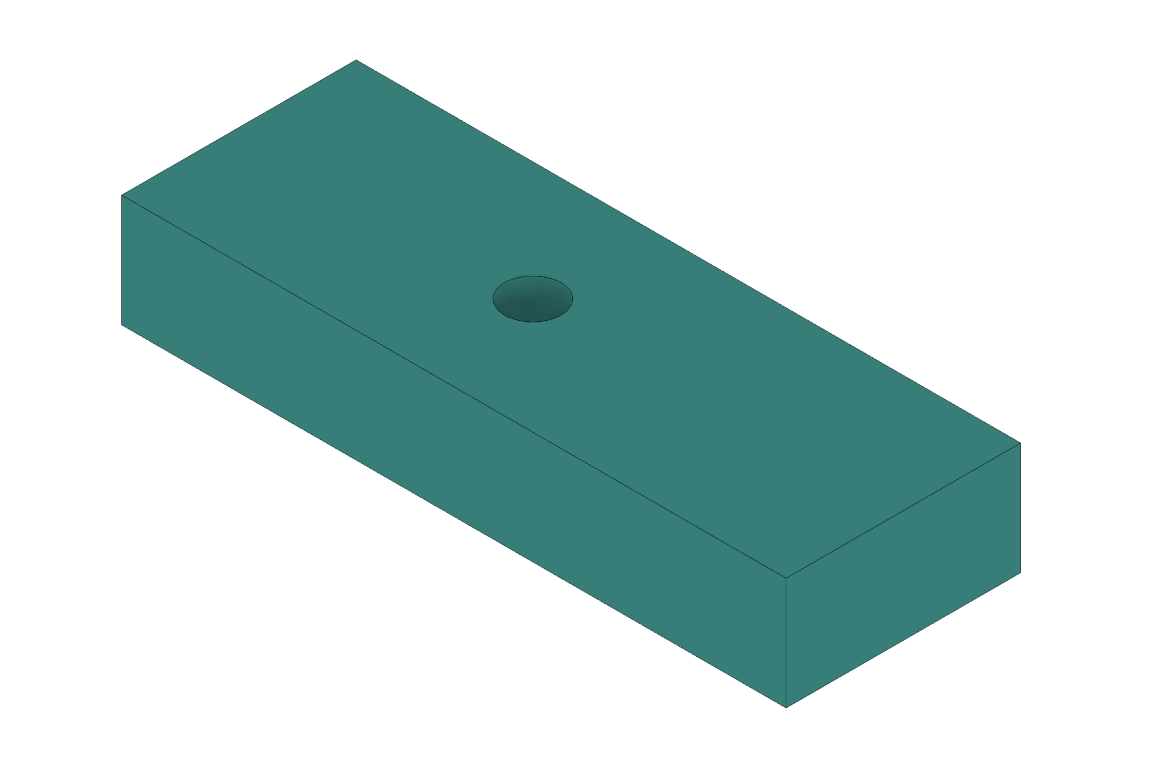

Minimum Hole Size

The smallest hole diameter that can be produced accurately

SLA

0.20 mm

FDM

1.0 mm

SLS

0.5 mm

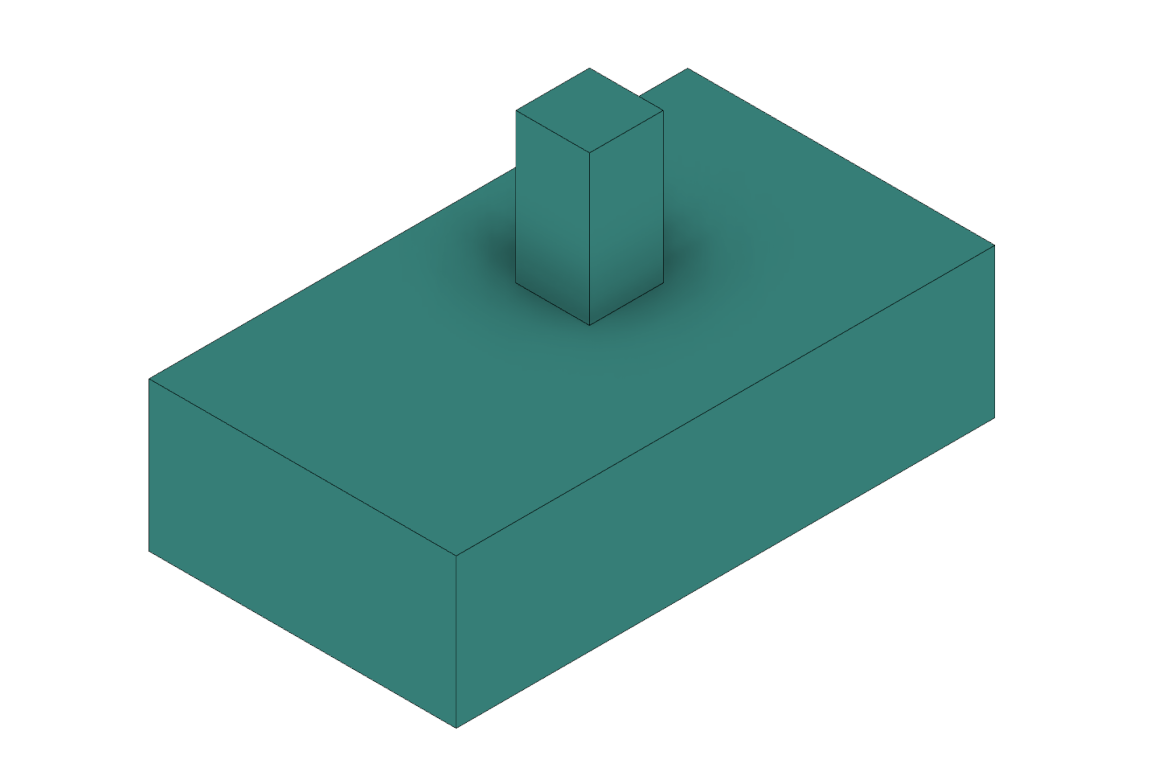

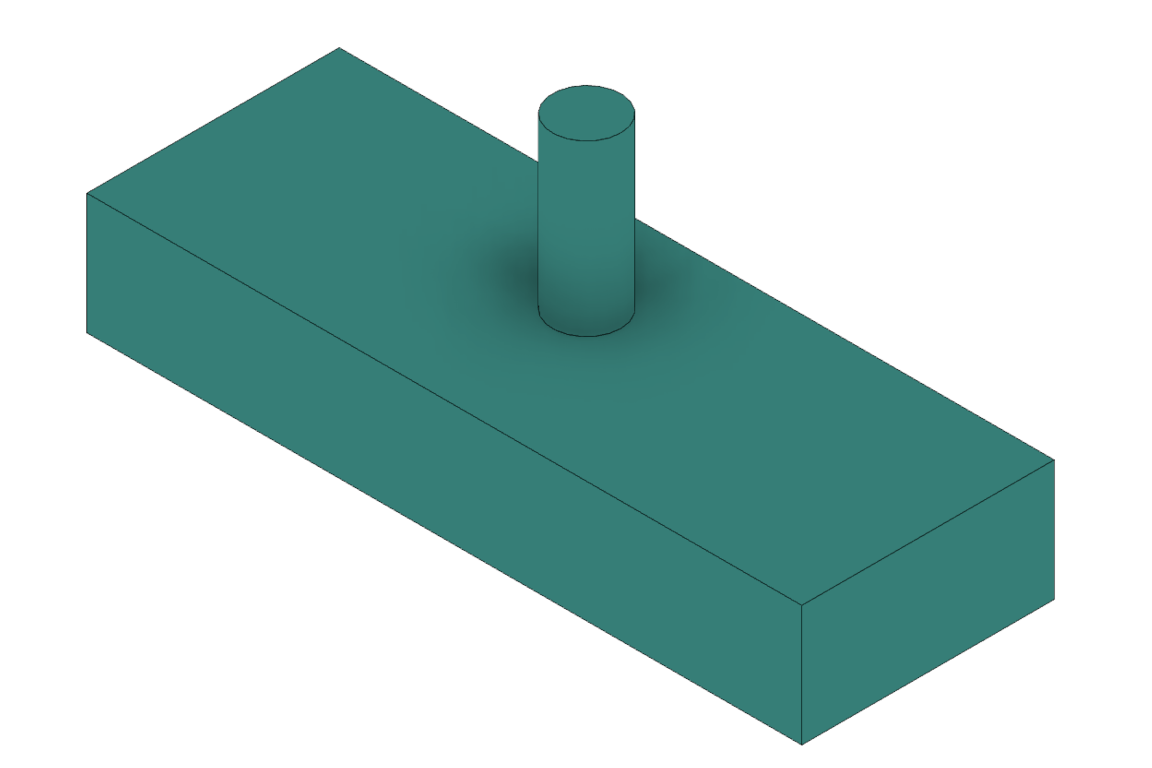

Minimum Pillar Size

The smallest pillar possible to produce accurately

SLA

1.00 mm

FDM

1.5 mm

SLS

1.00 mm

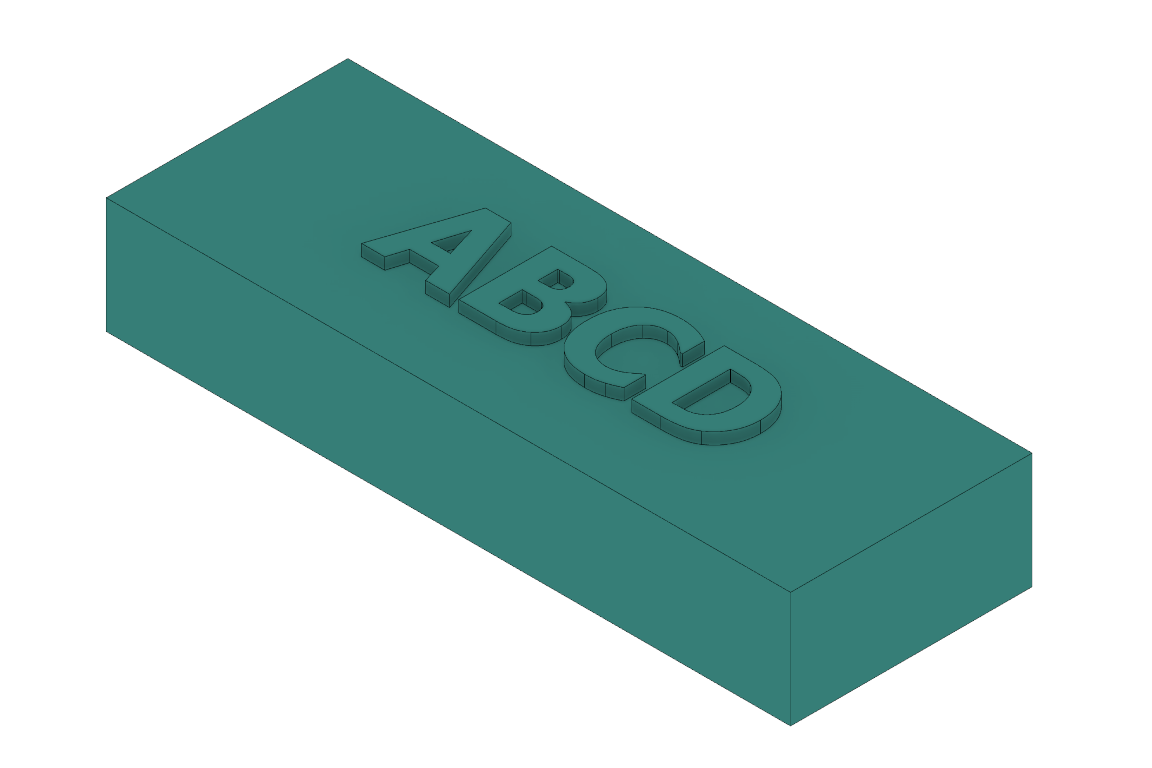

Minimum Text Height

The smallest height of letters required to produce accurately

SLA

3.53 mm (10-pt)

FDM

6.33 mm (18-pt)

SLS

4.94 mm (14-pt)

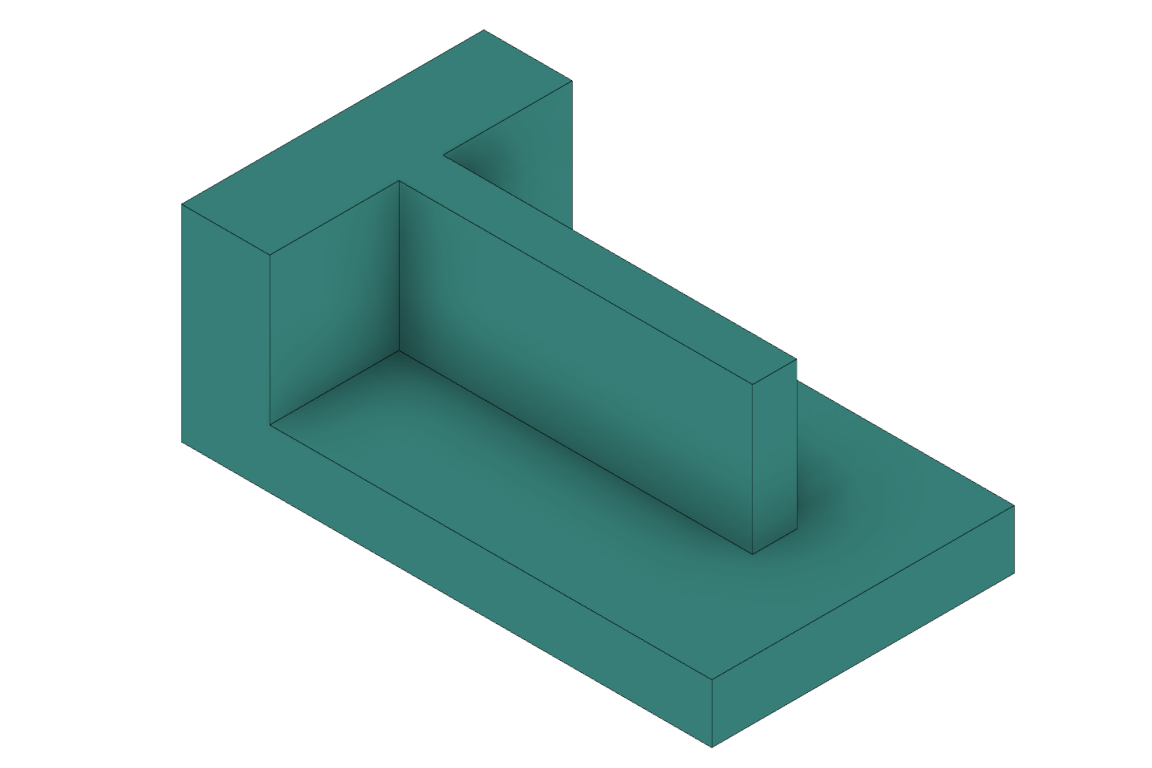

Maximum Supportless Angle

Supports are always removed before shipping, but may result in minor cosmetic surface defects

SLA

Always support

FDM

45°

SLS

No support

Manufacturing Standards

At RapAdd MFG, we operate our 3d printing service to some of the most strict and transparent quality standards on the market. We know that there are two aspects that are more important than most others in selecting an online manufacturing service: reliable on-time delivery and high-quality prints. We also know the importance of being able to trust the provider of the 3d printing service to deliver on their promises every single time.

Therefore, in order to provide an as high of a quality 3d printing service as possible, we want to make sure that you know of our quality standards before placing an order. Below you’ll find outlined an overview of the quality-standards to which your items are checked prior to dispatch.

Further down the page you’ll also find links to a full description of all the possible defects that are checked by our AQMS (Automated Quality Management System) prior to dispatch.

SLA

- All items must have a bounding box dimensional accuracy of ±0.5% (min ±0.15 mm)

- If bounding box measurements aren’t readily available to measure, the largest available feature will be measured.

- Items are oriented to minimize the impact of support material cosmetic surfaces. If this is not obvious from the model and the customer hasn’t specified a direction to print the items, the orienting algorithm will minimize the amount of support needed.

- All support-nibs are sanded smooth, using grit P400 sandpaper.

- Scratches from sanding or support removal are not allowed.

- Surface deviation on support connection points must be within ±0.15 mm of total deviation from the nominal surface.

- Surface deviation due to supported surfaces must be within ±0.20 mm of total deviation from the nominal surface.

- Items are washed in ultrasonic cleaner for a total of 20 minutes submerged in IPA.

- Items are cured to manufacturers specification.

- Remaining traces of uncured resin on or inside the finalised item are not allowed, unless geometrically impossible.

FDM

- All items must have a bounding box dimensional accuracy of ±0.5% (min ±0.5 mm)

- All items are built with a layer height of 0.24 mm.

- All surfaces must have a consistent appearance. Discolourations are not allowed.

- Dust and other particulates in the parts are not allowed.

- Items are oriented to minimize the amount of support material necessary to produce the item.

- Remains of other coloured plastics visible on the bottom surface of items are not allowed.

- All support material structures are removed and the supported surfaces must be consistent with each other.

- Remaining traces of PVA support material are not allowed and must be washed off.

- Layer inconsistencies must be within ±0.2 mm of total deviation from the nominal surface.

- If a cosmetic surface is selected, this surface should be completely free of support material.

SLS

- All items must have a bounding box dimensional accuracy of ±0.3% (min ±0.3 mm)

- All items are built with a layer height of 0.15 mm.

- PA12 powder is mixed at a ratio of 30/70 (virgin/reused).

- Items are built with wall thickness of 3.00 mm, and infill 30% for items with walls thicker than 6.00 mm to avoid warpage and surface inconsistencies.

- All excess powder and blasting media must be removed.

- All surfaces are consistently shot-peened.

- Items with large flat surfaces are oriented vertically to avoid warping or steps from layer changes.

- Dyed items are shot-peened after dyeing.

- Orange-peel effect in surfaces must be within ±0.10 mm of total deviation from the nominal surface.

- Warping of items must be within ±0.15 mm of total deviation from the nominal surface.

Lead-times & Service Production Options

RapAdd MFG offer several production options for our 3d printing service to suit every customer's need. This includes everything from lower budget orders where time is not a concern, to high priority parts requiring overnight delivery.

Regardless of what production option you choose, you can rest assured that we will always stick to the same high manufacturing standards and quality control.

Economy

Economy printing orders are for you who does not mind the wait. It offers a usual lead-time of around 14 days and your items are then sent using our economy level shipping service.

Standard

Our Standard printing option offers you a lead-time of 3 days until shipment. When the print is finished, it is sent straight to you using one of our reliable couriers.

Delivery Options

We do all of our deliveries through UPS, ensuring reliable transport and up to date tracking.