Technology Overview

SLA is the oldest 3d printing technology, and operates by selectively curing a very thin layer of liquid light-sensitive plastic, whereby the 3d printer builds parts one layer at the time. By using high-definition means of projecting light onto the photopolymer, with our industrial SLA 3d printers, we are able to build parts with details as small as just a few tenths of a millimeter.

By using a DLP projector to project a full layer at a time, our industrial SLA 3d printers can cure a full layer in just one second, allowing us to build hundreds, or even thousands of parts on a single printer within just a few hours.

Industrial SLA Use-cases

Visual Prototyping

With lead-times of just 1–2 days and surface-quality similar to injection molded parts, SLA is an ideal technology for producing visual prototypes and end-use products.

- Short lead-times

- Exceptional surface quality

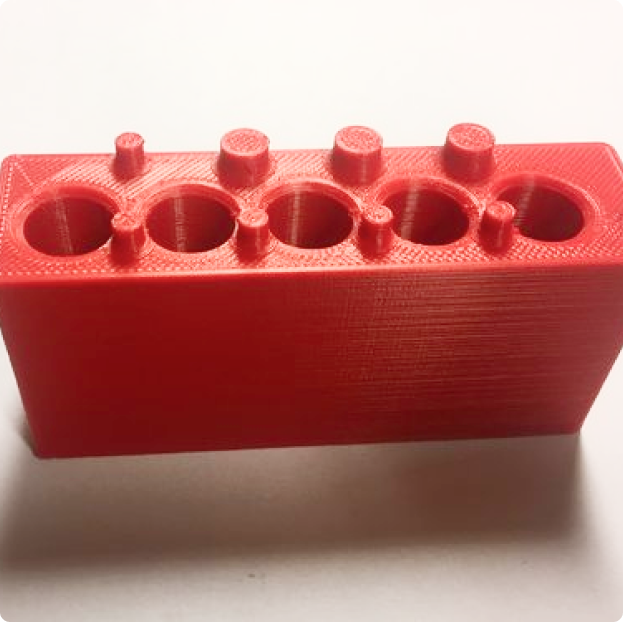

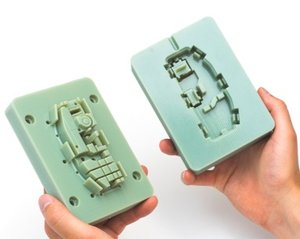

Injection Molds

With high temperature resins we can produce 3d printed injection molds within just a few days. Perfect to produce a few hundred injection-molded items.

- Prototype injection molded parts

- Fast turnaround

Volume Production

With no tooling required, short lead-times and a wide range of materials and colours available, SLA is a perfect choice for short and medium production runs.

- Volume discounts

- No tooling costs

- ABS-like materials

Our SLA Machinery

Our industrial SLA farm is a fully in-house designed system capable of unattended 24/7 operations. No matter how many parts are placed on a build-plate, our Industrial SLA 3d printers are capable outputting up to 100mm of build-height per hour, allowing us to print hundreds, or even thousands of objects each hour, all while providing 3d prints with a surface quality very similar to that of injection molded parts, but at a fraction of the cost.

SLA Materials

We carry a range of industrial resins for our SLA materials, from resins suitable to be used as casting patterns to high temperature resistant resins that can be used as low volume injection molding tools.

Polyjet Full Color

Using Polyjet technology, we produce highly detailed, full-color models with exceptional precision and finish options.

PA12 Carbonfiber

Carbon-fiber reinforced nylon. Added carbon-fiber makes this one of our stiffest materials.

High-detail Resin

Engineered to capture the smallest details. Great for parts with texts and extreme features.

Visual Resin

or "Standard Resin". Perfect for visual prototypes and decorative objects. Usually too brittle for functional parts.

PC

One of our strongest materials offered, perfect combination of mechanical properties and temperature stability.

Biodegradable PHA

Fully compostable, as well as being approved by the FDA for food contacts. Safe to use in a dishwasher.

PLA Metal-fill

PLA-based material composed of approximately 20-40% metal by weight. For aesthetic purposes.